Track Measurement with the Trimble GEDO Track System

It is true that railways played a major role in the development of our country. And although we all remember being children and looking in awe as these giant locomotives from CN or CP passed by, we must admit that taking the train is probably not the first thing that comes to mind for most Canadians when planning our next trip. Rail connections between Canada’s cities are not as developed as you would find in most major European countries, where taking the train is the easiest and most efficient way to get around.

However, what has been gaining traction in Canada for the last ten years is the expansion and creation of urban light rail transit, or LRT. Billions of dollars are being invested by all levels of government into rail projects across Canada. Vancouver, Calgary, Edmonton, Greater Toronto, and Ottawa are currently expanding their LRT networks. Montreal is working on a brand new 67-km LRT network with a 32-km extension already in the works. Quebec City and Hamilton have projects set to start soon as well.

LRT and track measurement are the new ‘cool kids’ on the block, but they come with a new set of notions and a language that I must admit were foreign to me before jumping into this product segment. Every surveyor can make sense of a center line or the edge of pavement, but hearing things like gauge, cant, twist, curvature, and chords requires a bit of research before we can even get started.

So here goes…

To help you out with the basics, gauge is the distance between the two inner rails of a track. In most places in Canada, the standard gauge of 1,435 mm (4 ft 8 1⁄2 in) is used, but you’d be surprised to learn that in Toronto they are using a slightly broader gauge (+60mm) for historical reasons. The cant, also referred to as superelevation, is commonly used to measure the difference in height between the two rails. As with a road design, the cant will be more pronounced on curves. The twist is calculated as the difference of cant over a specific distance. This value is important for ride comfort in general, but also for track safety (e.g. to prevent derailment) and to reduce wear on the track and the rolling stock.

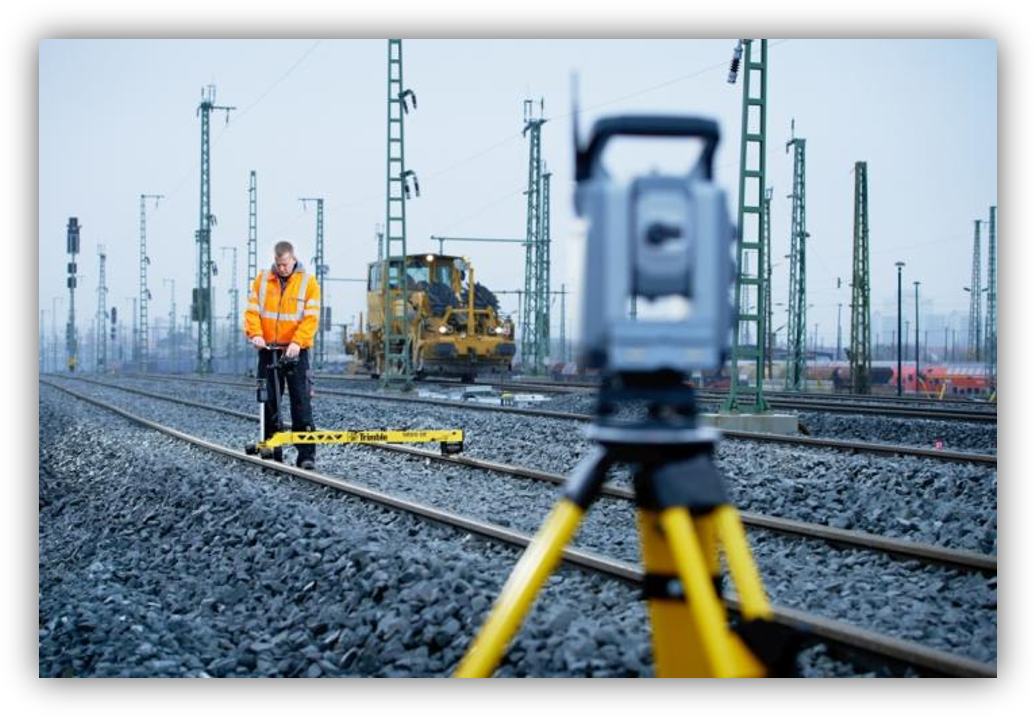

Some surveyors may be familiar with the rail shoe that allows you to take a measurement on the inner face of the rail. You can imagine how onerous it would be to take enough measurements to be able to extract the gauge, cant, and twist on top of XYZ coordinates for the track geometry on a long baseline. Fortunately, Cansel offers a solution to efficiently capture a large volume of track related measurements through the Trimble GEDO track surveying system. This modular trolley system can be paired with different sensors to accomplish a broad range of track related tasks, among them: basic track documentation and as-built surveys, track installation and production of correction data for the tamping machine. Software solutions are also provided to create reports, conduct clearance analyses, and track redesign.

The Trimble GEDO system is currently being used on several Canadian LRT projects.

.jpg?width=4032&name=29th_Avenue_platform_level_(20190626_123343).jpg)

Track Layout

For a new rail or expansion project, the main task is to install a track system where nothing existed previously. We can split this in to two categories. One is ballasted tracks, where a good layer of crushed stone is laid out before installing the rail ties to which the rails will be attached. It is later covered with another layer of ballast and then brought to the design geometry with several tamping runs. This consists of a huge machine with claws that locks on the rails with the ability to move them around. The other category is a lot less forgiving and is referred to as direct fixation or DF. This means that the rails are installed on a concrete foundation with very little room for adjustment after the final pour.

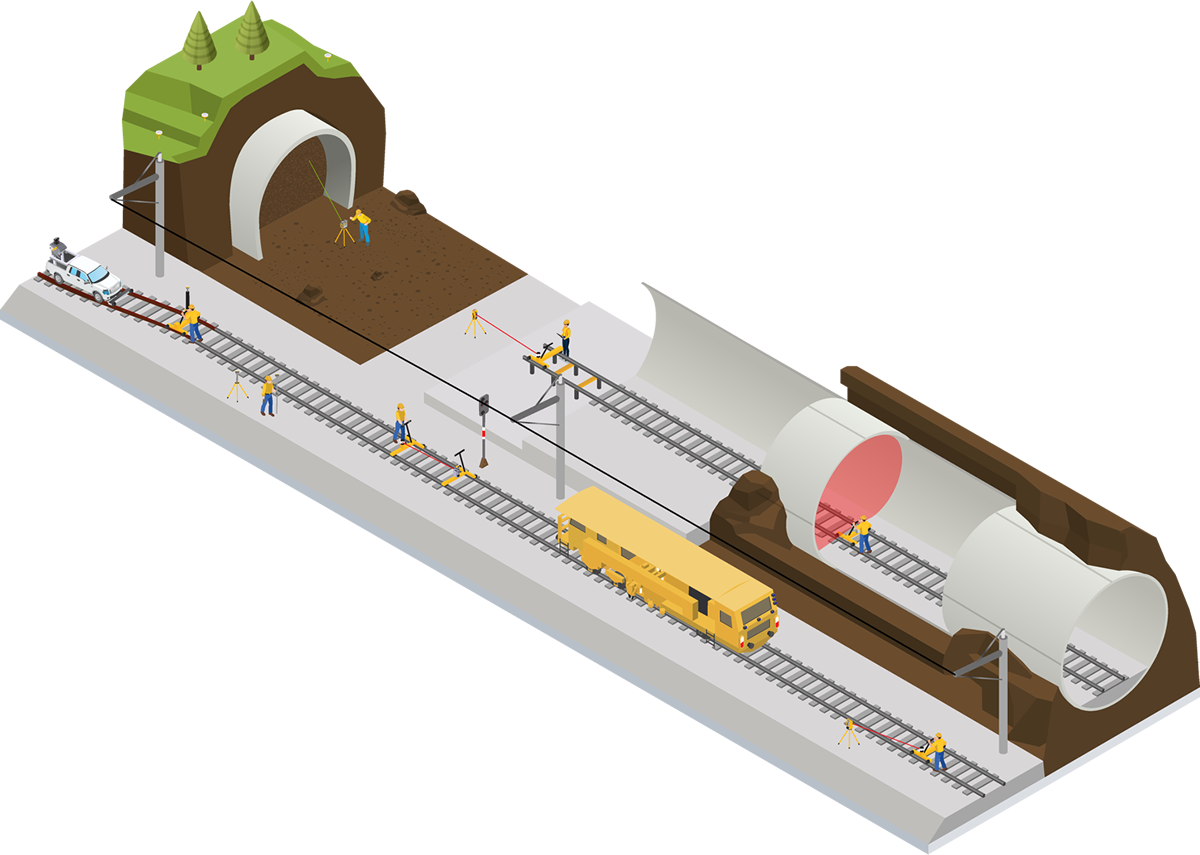

In both cases, the Trimble GEDO trolley will be used in conjunction with a high-accuracy total station to precisely adjust them to design specifications, live in the field. This geodetic approach to obtain mm precision relies on a dense and accurate control network. This is true for any project, but even more so with the long, linear nature of rail projects.

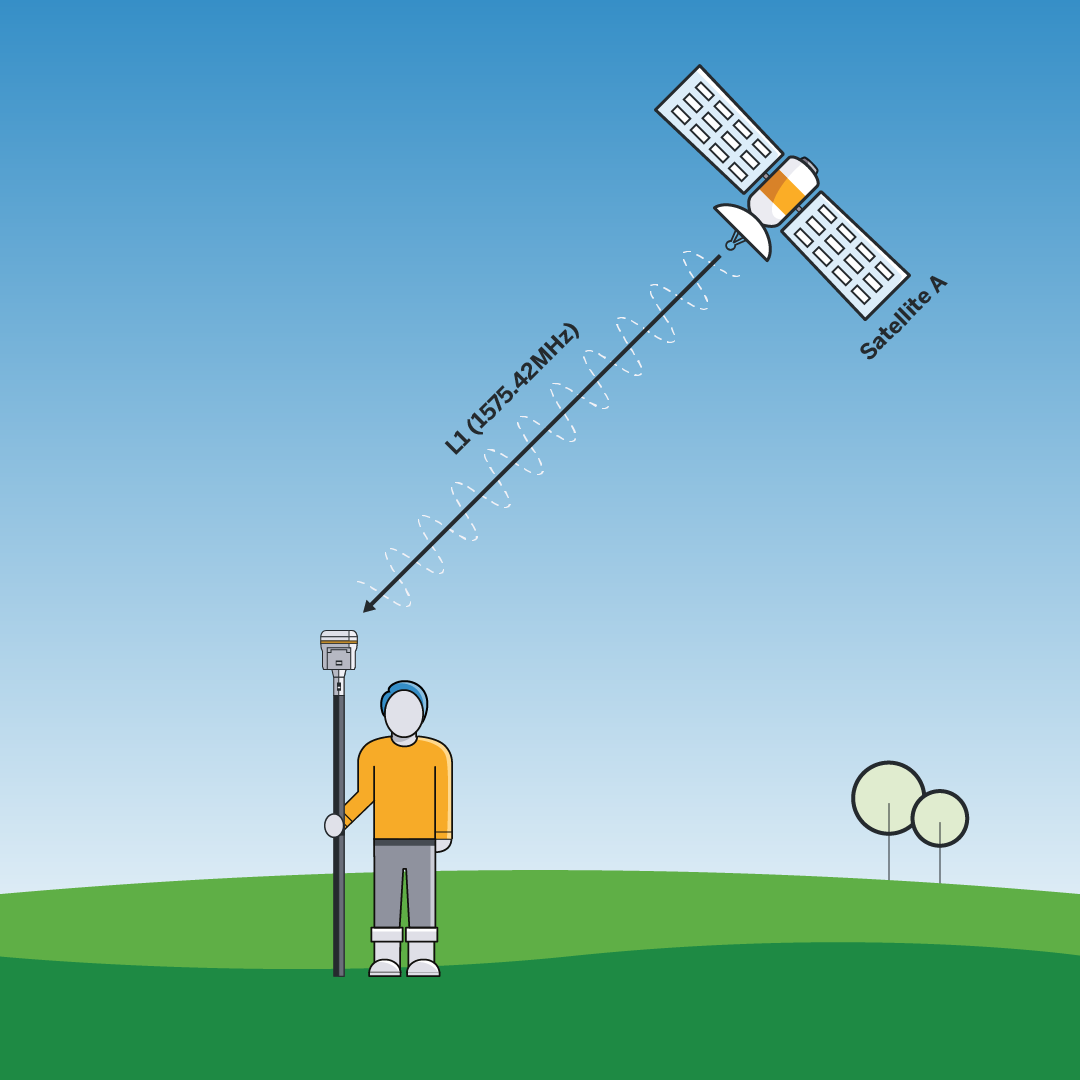

The usual workflow is to install the total station on a tripod over the lower rail, then calculate the position of the total station through a resection process with several control points, making sure to use overlapping control through each setup. Then the total station will take measurements to a high-accuracy prism installed on a known, fixed point on the trolley. The inner dimensions of the trolley having been established to the mm level through a calibration process at the factory, combined with the gauge and inclination sensors (accurate to the sub-mm level!), allows the field software with the track design data to control the track geometry parameters and provide live corrections during the rail installation process.

The Trimble GEDO system is currently being used on several Canadian LRT projects.

Pre-measurement for track tamping

Tamping machines are used to position new rails to design specifications and are a necessary tool for track maintenance. Tracks over ballast are nimble systems that are designed to deform under the weight of a train, then quickly rebound to their original position. Over time though, the constant stress of trains passing by will ultimately cause the track to diverge from the original design.

Credit: www.plasseramerican.com

Most tamping machines work in a relative position mode. This means that they will operate over a small length of track to collect geometry data, and then smooth out that area without comparing it to the overall track design. Once again, this is where the Trimble GEDO trolley solution steps up. In the previous section, we explained how we could use a geodetic approach to stake out track to the intended design. And you would be right if the thought occurred to you to use these measurements to feed the tamping machine. But as you know, setting up a total station and having to move it every few hundred meters is a slow process. Therefore, something more efficient is required.

On your next trip to Ottawa or Montreal, you might come across an LRT project using the ingenious dual trolley system with a total station installed on one of the trolleys. This is called the GEDO Vorsys.

Trimble GEDO Vorsys

With this system, we can calculate chords along the design data by taking measurements with the total station (installed on a trolley) to two perpendicular control points a few dozen meters apart. The second trolley carrying a prism is then pushed towards the instrument. This allows us to compare the measured versine to the design versine which can be transformed into accurate corrections. They can then be easily transferred from the office software to the tamping machine via a USB stick. This method is very efficient, and most importantly allows us to cover up to 1.5 kilometres of track per hour. Speed becomes an important factor, given that the installation of new track can take four to seven tamping runs to get to the desired position.

Modern tamping machines can use the correction file and proceed to tamping automatically without the need for the operator to touch the controls!

These two applications are most common for our numerous Canadian LRT projects. However, we could also have talked about how to add a laser scanner to the trolley system to capture a high density as-built model of the track and its surroundings. This data could then be combined with a 3D wagon model to analyze clearance and collision conditions. And look for the addition of inertial measurement systems to the GEDO trolley system as well. This will add a whole new dimension of efficiency to the tasks performed in the maintenance and operation phase of these projects. We’ll leave this for a follow-up article.

To learn more about the Trimble GEDO track system, or to discover the large solution portfolio we offer to the track surveying world, please contact your Cansel representative.